Edinburgh-headquartered rocket firm Skyrora fuelling ambitions with pioneering new device

and live on Freeview channel 276

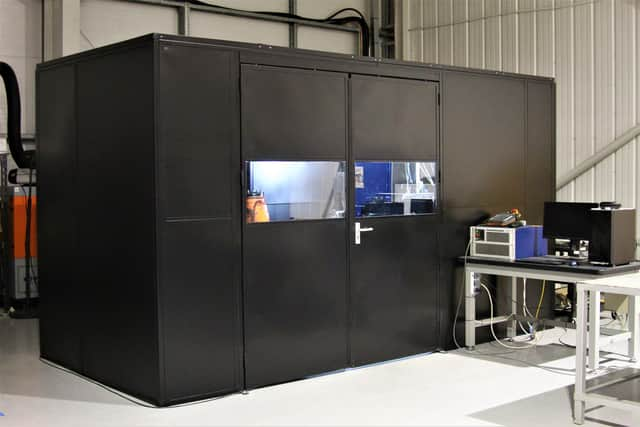

The Skyprint 2 device is expected to offer a cost-effective, bi-metallic, hybrid manufacturing service to meet the growing demand for small satellite launches. It is set to start production in the second quarter of next year, capable of making parts up to 2.3 metres high.

The firm, which has astronaut Tim Peake on its advisory board, said the new device will reduce process complexity, cost and printing time by around 30 per cent compared to other printers.

Advertisement

Hide AdAdvertisement

Hide AdVolodymyr Levykin, Skyrora’s founder and chief executive, said: “Skyprint 2 reinforces our ambitions to not only be the first company to launch from UK soil, but also to do so in the most sustainable way possible. By taking greater control of the design and manufacturing process of our parts using our custom-built industry-leading 3D printing technology, we are taking another crucial step closer to offering a significant space service from our own soil.

"Creating this cost- and time-effective solution encapsulates the innovation and talent that resides at the heart of the UK space industry. As an asset, Skyprint 2 is a real game-changer – it will transform Skyrora’s operations and expand the limits of what is possible when it comes to space engineering in general.”

The development comes after the business completed trials of the third stage of the Skyrora XL rocket, and in October announced an agreement with Shetland spaceport SaxaVord that will enable it to complete 16 launches a year by 2030.

A message from the Editor:

Thank you for reading this article. We're more reliant on your support than ever as the shift in consumer habits brought about by coronavirus impacts our advertisers.

If you haven't already, please consider supporting our trusted, fact-checked journalism by taking out a digital subscription.

Comment Guidelines

National World encourages reader discussion on our stories. User feedback, insights and back-and-forth exchanges add a rich layer of context to reporting. Please review our Community Guidelines before commenting.